M10 X 1.5 BAERFIX KITS

M10 X 1.5 BAERFIX KITS is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Shipping Information

Place your order before 2 PM for same-day shipping!

We partner with DPD for all deliveries, ensuring full traceability and a one-hour delivery window, so you don’t have to wait around all day.

Shipping Cost: €8.99

Free Shipping: On orders over €50

Fast, reliable, and hassle-free delivery—straight to your door!

We ship with DPD

Order before 2pm for next day delivery

Need to collect? We are open 9am - 5pm Mon Friday Saturday 10am - 4PM

Description

Description

BaerFix Thread Repair Kit M 10 x 1.5 - ECO

With the BaerFix® thread repair set, damaged M 10 threads can be repaired quickly and easily.

This set contains all the tools you need to achieve a permanent and strong anchorage in various materials. The BaerFix® thread repair set is ideal for materials such as aluminium, light metals, non-ferrous metals, brass, bronze, cast iron, plastics, laminates and hardwood. Please note that the set is only suitable for materials with a tensile strength up to approx. 450 N/mm².

BaerFix® thread inserts are self-tapping, guarantee a permanently tight threaded connection in your workpiece and are extremely easy to use. Simply screw into the hole - the inserts cut the holding thread themselves. Once your thread is worn or torn out, a stable connection between the materials is no longer possible. This is where BaerFix® thread insert comes to the rescue. With our self-tapping thread inserts you can repair or strengthen damaged internal thread. Damaged threads in your components do not have to be rejects. Simply insert a threaded insert with the same internal thread into the component and your thread will not only be repaired, it will also be more pull-out resistant and wear resistant. The pull-out strength is higher than a class 8.8 screw.

To assist with the repair, the set includes a core drill bit and an assembly tool in addition to the thread inserts. Use the core drill bit to prepare the core hole and the installation tool to insert the self-tapping thread insert.

Dimensions

| Diameter | 10 |

|---|---|

| Pitch | 1,5 |

| Dimension | M 10 x 1,5 |

Characteristics

| Product group | Self-cutting thread inserts - Thread repair kits |

|---|---|

| Product type | BaerFix thread repair kits |

| Thread standard | M: Metric ISO standard thread according to DIN 13 |

| Tolerance | ISO2/6H |

| Direction | Right |

| Type | with cutting slots |

| Material | Case-hardened steel, galvanized |

Guidelines for material machining

| Maximum insertion torque | 40 Nm |

|---|---|

| Speed guide value for light metals | 200-300 R/min |

| Drilling depth | Min. drilling depth for through hole: 18.00 mm Min. drilling depth for blind hole: 22.00 mm |

| Pre-drilling diameter | Light metal alloys (tensile strength below 250 N/mm²): 12.8 mm Light metal alloys (tensile strength 250 - 300 N/mm²): 13.0 mm Light metal alloys (tensile strength 300 - 350 N/mm²): 13.2 mm Light metal alloys (tensile strength over 350 N/mm²): 13.4 mm Brass, non-ferrous metals, bronze (tensile strength over 350 N/mm² ): 13.2 - 13.4 mm Cast iron(Brinelhardness under 150 HB): 12.8 mm Cast iron(Brinel hardness 150 - 200 HB): 13.0 - 13.2 mm |

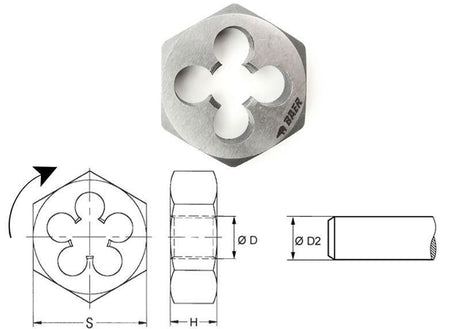

Technical drawing

| D1 | M 10 x 1,5 |

|---|---|

| D2 | M 14 x 1,5 |

| L1 | 18 mm |

| Diameter | 10 |

Content

- 1 x 1-111132: BaerFix HSS twist drill bit with countersunk shank 13.25 mm

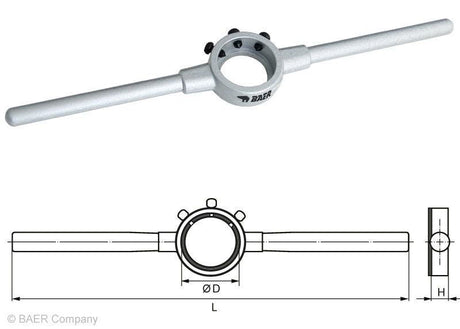

- 1 x 1-KEBW10: BaerFix Installation tool M 10

- 1 x B9501: BaerFix adapter nut

- 5 x FE10: BaerFix self-tapping thread inserts with cutting slots M 10 x 1.5 - length: 18 mm - material: case-hardened steel, galvanised

Minimum wall thickness

| materials |

|---|

| Rmin (light metal): 2.80 mm Rmin (cast iron): 4.20 mm Rmin (plastic): 3.50 mm |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Size Matters!

No one in Ireland stocks the size range we do. Whether you need a pack of 2 or a box of 2,000 we've got you covered.

Product comparison grid

Add content here to explain a bit about the range of products on offer and which ones may be most suitable for your customers.