1" X 11 X 1.5D BSP BAERCOIL INSERTS 5Pck

1" X 11 X 1.5D BSP BAERCOIL INSERTS 5Pck is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Shipping Information

Place your order before 2 PM for same-day shipping!

We partner with DPD for all deliveries, ensuring full traceability and a one-hour delivery window, so you don’t have to wait around all day.

Shipping Cost: €8.99

Free Shipping: On orders over €50

Fast, reliable, and hassle-free delivery—straight to your door!

We ship with DPD

Order before 2pm for next day delivery

Need to collect? We are open 9am - 5pm Mon Friday Saturday 10am - 4PM

Description

Description

BaerCoil Wire Thread Inserts G (BSP) 1“ x 11 - 1.5 D (38.1 mm) - free running - 5 pcs.

BaerCoil® thread inserts are the best solution for all your repair needs! With them you can create long-lasting and powerful connections. These inserts also ensure that you have no waste and recycle everything. The inserts are precise and wear resistant - your screw will stay firmly in place without the thread insert slipping.

The BaerCoil® thread insert is the perfect solution for damaged threads. STI thread (screw thread insert) is cut and the BaerCoil® insert is screwed in. The thread produced is significantly stronger than the original thread.

BaerCoil® thread inserts ensure optimum power transmission from the bolt to the nut thread - even in lightweight constructions. Due to their flexibility, they can compensate for pitch and angle errors and thus guarantee optimum force transmission. BaerCoil® thread inserts are already important components in the aerospace and automotive industries and help to reduce carrier material and use smaller, shorter bolted joints.

BaerCoil® thread inserts can be shortened, according to the required length, with a side cutter or similar.

Dimensions

| Diameter | 1" |

|---|---|

| Pitch | 11 |

| Dimension | G (BSP) 1" x 11 |

| Length | 1,5 D |

| T (Length when installed) | 38,1 mm |

| Thread length calculation | 1.5 D means 1.5 times the calculation diameter: 1.5 times 25.4 mm=38.1 mm The nominal diameter for G (BSP) 1" is approx. 33.25 mm, but according to the standard the length is calculated with the diameter of 25.4 mm for calculation purposes |

Characteristics

| Product group | Wire thread inserts |

|---|---|

| Product type | BaerCoil wire thread inserts |

| Thread standard | G (BSP): British Standard Pipe Thread according to DIN ISO 228 - Cylindrical pipe thread |

| Direction | Right |

| Type | free running |

| Tensile strength at room temperature | >1400 N/mm² |

| Material | Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance | 315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and thread reinforcement

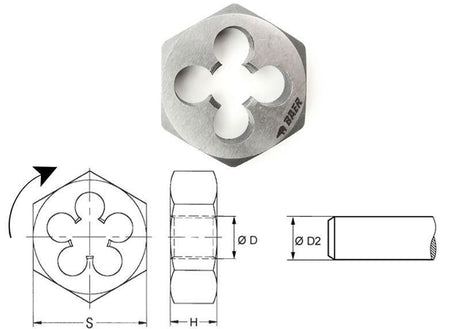

Technical drawing

| Diameter | 1" |

|---|---|

| Length | 1,5 D |

| T (Length when installed) | 38,1 mm |

| F (Min. - Max. outside diameter of thread insert) | 1,416 '' - 1,543 '' |

| P (depth) | The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) | 1,819 '' |

| D (minimum depth of the core hole, without tip) | 1,910 '' |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Size Matters!

No one in Ireland stocks the size range we do. Whether you need a pack of 2 or a box of 2,000 we've got you covered.

Product comparison grid

Add content here to explain a bit about the range of products on offer and which ones may be most suitable for your customers.