1 1/4 UNC BAERCOIL KIT B4118

1 1/4 UNC BAERCOIL KIT B4118 is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Shipping Information

Place your order before 2 PM for same-day shipping!

We partner with DPD for all deliveries, ensuring full traceability and a one-hour delivery window, so you don’t have to wait around all day.

Shipping Cost: €8.99

Free Shipping: On orders over €50

Fast, reliable, and hassle-free delivery—straight to your door!

We ship with DPD

Order before 2pm for next day delivery

Need to collect? We are open 9am - 5pm Mon Friday Saturday 10am - 4PM

Description

Description

BaerCoil Thread Repair Kit UNC 1.1/4 x 7

With this BaerCoil® thread repair set it is possible to repair through hole and blind hole threads in UNC 1.1/4" x 7.

BaerCoil® thread inserts are the best solution for all your thread repair needs! With them you are able to make durable and strong connections. With the inserts you avoid waste in your components and can recycle them. The inserts are precise and wear resistant - your screw will stay firmly in place without the thread insert slipping out.

The BaerCoil® thread insert is the perfect solution for damaged threads without changing the nominal diameter. For the thread repair with wire thread inserts, the thread is drilled out and a new STI thread (screw thread insert) is cut for the wire thread insert. This thread is often also called STI thread (STI=Screw Thread Insert). Then the BaerCoil® thread insert is screwed into the old thread and thus the workpieces are screwed back together. With BaerCoil® thread inserts, the thread produced is significantly more stable than the original thread.

Our thread inserts ensure that both static and dynamic work loads are distributed evenly over the individual thread turns. In addition, the flexibility of the thread inserts compensates for possible pitch and angular errors, so that optimum force transmission from the bolt to the nut thread is achieved. Especially in lightweight constructions, BaerCoil® thread inserts help to save carrier material and to use smaller or shorter screw connections. They are already an important component in aviation and vehicle construction. They significantly save material and contribute to the conservation of resources.

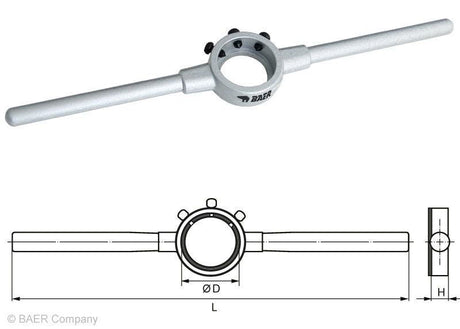

For repair directly on the thread, this thread repair set contains various auxiliary tools, such as the hand tap with oversize for insert threads, insertion tool and wire thread inserts made of stainless steel.

This set does not include twist drill bit and tang breaker. To drill the core hole, a 33 mm twist drill bit is still needed here. The tenon can be broken with the installation tool. To do this, pull the installation tool back after installation and turn it 90° so that it rests on the tenon. Then strike the tool briefly at the back.

BaerCoil® thread inserts can be shortened, if necessary, to the required length with a side cutter or similar.

Dimensions

| Diameter | 1.1/4" |

|---|---|

| Pitch | 7 |

| Dimension | UNC 1.1/4" x 7 |

| Length | 1,5 D |

| T (Length when installed) | 47,63 mm |

| Thread length calculation | 1.5 D means 1.5 times the diameter: 1.5 times 31.75 mm=47.63 mm The nominal diameter at UNC 1.1/4" is approx. 31.75 mm |

Characteristics

| Product group | Wire thread inserts - Repair kits |

|---|---|

| Product type | BaerCoil thread repair kits |

| Thread standard | UNC: American Unified National Coarse thread according to ANSI B1.1 |

| Direction | Right |

| Type | free running |

| Tensile strength at room temperature | >1400 N/mm² |

| Material | Stainless Steel V2A (AISI 304, X5CrNi18-10, Material No.: 1.4301) |

| Temperature resistance | 315°C long-term 425°C short-term |

Applications

All normal uses for thread repair and for thread reinforcement of through-hole and blind-hole threads.

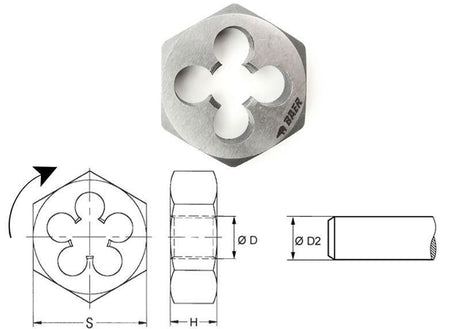

Technical drawing

| Diameter | 1.1/4" |

|---|---|

| Length | 1,5 D |

| T (Length when installed) | 47,63 mm |

| F (Min. - Max. outside diameter of thread insert) | 1,413 '' - 1,483 '' |

| P (depth) | The thread insert must sit 1/4 - 1/2 turns below the surface |

| B (thread depth with chamfer) | 2,375 '' |

| D (minimum depth of the core hole, without tip) | 2,518 '' |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Size Matters!

No one in Ireland stocks the size range we do. Whether you need a pack of 2 or a box of 2,000 we've got you covered.

Product comparison grid

Add content here to explain a bit about the range of products on offer and which ones may be most suitable for your customers.