1/4x20 UNC L/H TAP SET -

1/4x20 UNC L/H TAP SET - is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Shipping Information

Place your order before 2 PM for same-day shipping!

We partner with DPD for all deliveries, ensuring full traceability and a one-hour delivery window, so you don’t have to wait around all day.

Shipping Cost: €8.99

Free Shipping: On orders over €50

Fast, reliable, and hassle-free delivery—straight to your door!

We ship with DPD

Order before 2pm for next day delivery

Need to collect? We are open 9am - 5pm Mon Friday Saturday 10am - 4PM

Description

Description

BAER HSSG Hand Tap Set (3pcs.) UNC 1/4 x 20 - LEFT

The left-hand tapping hand tap set consists of three taps and enables you to cut a finished left-hand thread with significantly reduced risk of breakage. One left-hand thread is tapped counterclockwise. The left-hand tap or left-hand screw tap is also operated counterclockwise.

The advantage of three-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with one ring) removes 65 per cent of the thread profile and the intermediate tap (No. 2) (marked with two rings) removes 85 per cent. Pre-cutting and reworking with the intermediate tap (No. 2) bring the thread into shape. In the last step, the finishing tap (No. 3) is used, which has no ring marking. Only this cuts the full and usable thread at the end. The division of labour between the three screw tap makes it easier to cut a straight and clean thread by hand.

Compared to the machine tap, the hand tap has a short shank. This allows you to cut internal thread by hand without jamming and can be operated with tap wrenches, tool ratchets or other holding tools with square drive.

The thread can be cut in a pre-drilled core hole.

Due to the short chamfer of the finish tap, the hand tap set can be used reliably and universally for through holes and blind holes.

As a rule, three-piece hand taps- sets are used for regular threads with coarse pitch, as the thread profile area is larger than for fine threads and the force effects on the taps are greater.

Dimensions

| Diameter | 1/4 |

|---|---|

| Nominal diameter in inches | 0,25 |

| Nominal diameter in mm | 6,35 |

| Pitch | 20 |

| Pitch in mm | 1,27 |

| Dimension | UNC 1/4 x 20 |

| Square | 4,9 mm |

Characteristics

| Product group | Screw taps |

|---|---|

| Product type | Hand tap sets |

| Thread standard | UNC: American Unified National Coarse thread according to ANSI B1.1 |

| Tolerance | 2B |

| Direction | Left |

| Standard | DIN 352 |

| Tensile strength at room temperature | up to 900 N/mm² | 27.1 HRC |

| Material | HSSG bright |

5.2 mm

Through hole and blind hole up to 2 x D

Form C straight fluted

2-3 threads

Rarely occurs. Chips remain in flutes.

External cooling and lubrication

HSSG bright

up to 900 N/mm² | 27.1 HRC

2B

Applications

- Materials with good machinability up to 900 N/mm²

- Unalloyed and low-alloy steels

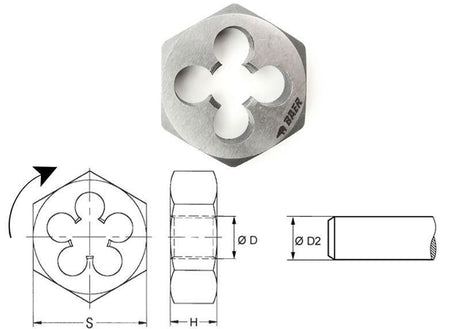

Technical drawing

| D1 | UNC 1/4 x 20 |

|---|---|

| D2 | 6 mm |

| L1 | 50 mm |

| L2 | 19 mm |

| Diameter | 1/4 |

| Square | 4,9 mm |

Application – Sample materials for taps

| Unalloyed construction steels | |

|---|---|

| 1.0035 | S185 (St33) |

| 1.0036 | S235JRH |

| 1.0038 | RSt37-2 |

| 1.0039 | S235JRG1+CR |

| 1.0044 | St44-2 |

| 1.0060 | E335 (St60-2) |

| 1.0116 | St37-3 |

| 1.0570 | St 52-3 |

| Alloyed construction steels | |

|---|---|

| 1.5415 | 15Mo3 |

| 1.5423 | 16Mo5 |

| 1.5622 | 14Ni6 |

| 1.7335 | 13CrMo44 |

| 1.7337 | 16CrMo44 |

| 1.7715 | 14MoV63 |

| Free-cutting steels | |

|---|---|

| 1.0711 | 9S20 |

| 1.0715 | 9SMn28 |

| 1.0718 | 11SMnPb30 |

| 1.0721 | 10S20 |

| 1.0723 | 15S20 |

| 1.0726 | 35S20 |

| 1.0737 | 9SMnPb36 |

| 1.0758 | 60SPb20 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck45) |

| Cast steel | |

|---|---|

| 1.0420 | GS-38 |

| 1.5419 | GS-22 Mo 4 |

| 1.6750 | GS-20 NiCrMo3 7 |

| 1.7357 | GS-17 CrMo 5 5 |

| Malleable cast iron | |

|---|---|

| 0.8145 | EN-GJMB 450-6 |

| 0.8170 | EN-GJMB 700-2 |

| 0.8045 | EN-GJMW-450-7 |

| 0.8055 | EN-GJMW-550-4 |

| Pure copper low-alloyed | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

| Brass short-chipping | |

|---|---|

| 2.0401 | CuZn39Pb3 |

| Brass long-chipping | |

|---|---|

| 2.0321 | CuZn37 |

| 2.0335 | CuZn36 |

| 2.0360 | CuZn40 |

| Aluminum cast Si > 5-12 % | |

|---|---|

| 3.2161 | G-AlSi8Cu3 |

| 3.2163 | G-AlSi9Cu3 |

| 3.2381 | G-AlSi10Mg |

| 3.2583 | G-AlSi12(Cu) |

| Lamellar graphite cast iron | |

|---|---|

| 0.6010 | EN-GJL 100 (GG-10) |

| 0.6020 | EN-GJL 200 (GG -20) |

| 0.6025 | EN-GJL 250 (GG-25) |

| 0.6030 | EN-GJL 300 (GG -30) |

| Copper-tin alloy (bronze) short-chipping | |

|---|---|

| 2.1090.01 | G-CuSn7ZnPb |

| 2.1086.01 | G-CuSn10Zn |

| 2.1097 | G-CuSn5ZnPb |

| Pure copper, low-alloyed copper | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Size Matters!

No one in Ireland stocks the size range we do. Whether you need a pack of 2 or a box of 2,000 we've got you covered.

Product comparison grid

Add content here to explain a bit about the range of products on offer and which ones may be most suitable for your customers.